Types, Techniques, and Industrial Importance of Metal Processing

Metal processing is a broad manufacturing process that includes cutting, shaping, drilling, welding, or surface treatment of metals. This process transforms raw metal materials into high-precision parts, structural components, and industrial products.

Today, metal processing technologies are used in many sectors such as construction, automotive, machinery manufacturing, energy, and defense.

What is Metal Processing?

Metal processing is the process of shaping raw metal using physical or mechanical methods. During this process, metal materials are formed into the desired shape through cutting, bending, welding, machining, forging, casting, and surface treatment.

The goal is to produce metal parts with high durability, precise tolerances, and aesthetic surface quality.

Metal Processing Methods

Metal processing is generally divided into three main categories:

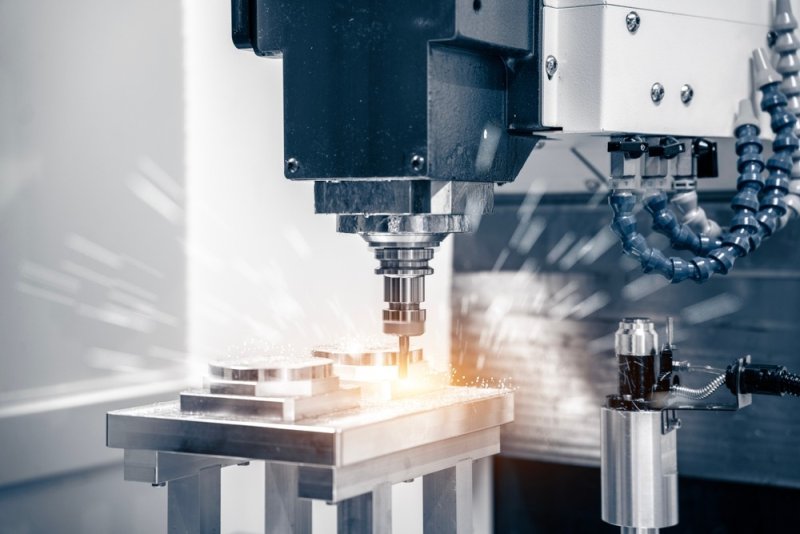

1. Chip Removal Processing

Metal is shaped by removing material from its surface to achieve the desired dimensions and shape.

Example processes:

- Turning

- Milling

- Drilling

- Grinding

- CNC machining

This method is preferred for producing high-precision parts.

2. Forming

Metal material is shaped in molds using heat or mechanical force.

Main methods:

- Bending

- Rolling

- Pressing

- Forging

These processes are commonly used in the production of sheet metal components.

3. Welding and Joining

Processes used to join two or more metal parts.

Common welding types:

- MIG / MAG Welding

- TIG Welding

- Electric Arc Welding

- Laser Welding

- Spot Welding

Welded manufacturing is crucial in steel structures, piping systems, and machinery production.

4. Surface Treatment

Processes to protect metal surfaces from wear, corrosion, or external effects.

Example processes:

- Sanding

- Polishing

- Painting

- Galvanizing

- Anodizing

Surface treatments enhance the aesthetics and durability of metal products.

Metal Processing Technologies

Modern metal processing is supported by advanced machinery and automation systems.

CNC Technology

Computer-assisted cutting and shaping operations provide high precision, mass production capability, and low error rates.

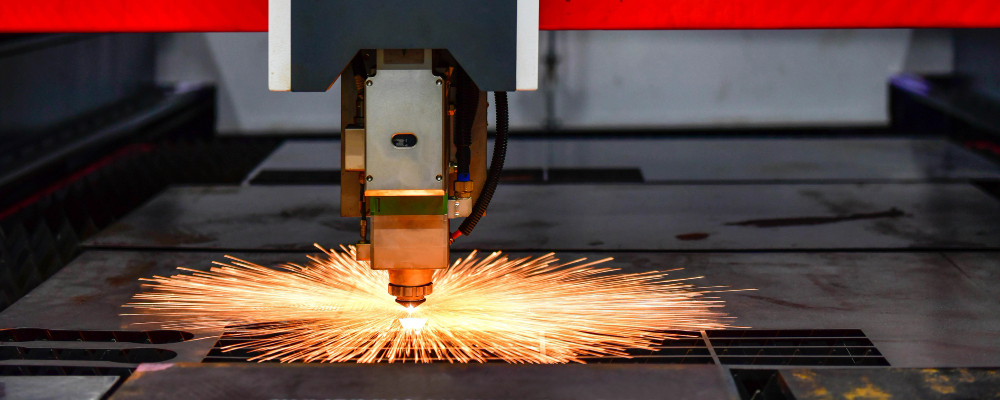

Laser Cutting

Allows precise cutting of metal using a laser beam.

- High cutting quality

- Complex geometries can be easily produced

Plasma and Water Jet Cutting

Enable fast and smooth cutting of thick metal plates.

Robotic Welding Systems

Industrial robots perform welding operations quickly, consistently, and accurately.

Materials Used in Metal Processing

Materials commonly used in metal processing:

| Material | Properties | Application |

|---|---|---|

| Carbon Steel | Durable, cost-effective | Construction, machinery |

| Stainless Steel | High corrosion resistance | Food, chemical, architecture |

| Aluminum | Lightweight, formable | Transportation, decoration |

| Copper | Good conductivity | Electrical systems |

| Titanium | Lightweight, high strength | Aerospace, defense |

Equipment Used in Metal Processing

- Lathes

- Milling Machines

- Press and Hydraulic Systems

- CNC Routers and Laser Cutting Machines

- Welding Robots

- Surface Grinding and Polishing Machines

These machines improve production efficiency by ensuring high quality and repeatability.

Importance of Metal Processing in Industry

- Strong and Durable Products: Processing steel, aluminum, and stainless metals results in high-strength structures.

- High Precision: CNC systems provide millimeter accuracy.

- Industrial Efficiency: Suitable for mass production, saving time and cost.

- Design Flexibility: Allows production of parts in different geometries and sizes.

- Sustainability: Metals are recyclable and environmentally friendly.

Quality Standards in Metal Processing

Metal processing is carried out according to international quality standards:

- ISO 9001: Quality management system

- ISO 3834: Welding quality standard

- EN 1090: Steel structure manufacturing standard

- ASME: Standard for pressure vessels

These standards ensure product safety and consistent quality.

The Future of Metal Processing and Automation

With Industry 4.0, automation, artificial intelligence, and robotic systems have been integrated into metal processing processes.

- Production lines are continuously monitored with smart sensors.

- Data analytics reduces error rates.

- Autonomous machines minimize human errors.

These advancements make the metal processing industry faster, more efficient, and sustainable.

Metal processing is one of the cornerstones of modern industry. Advanced technologies transform metal materials into durable, aesthetic, and functional products.

Whether it’s a steel structure, a machine part, or a decorative item, the right metal processing techniques ensure high quality, long lifespan, and safe use.