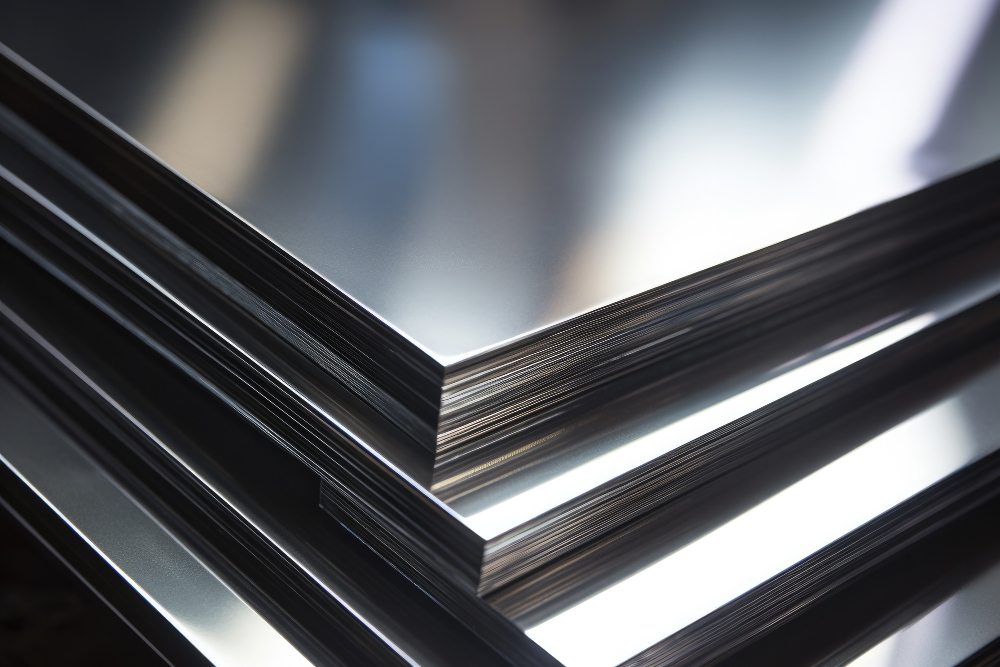

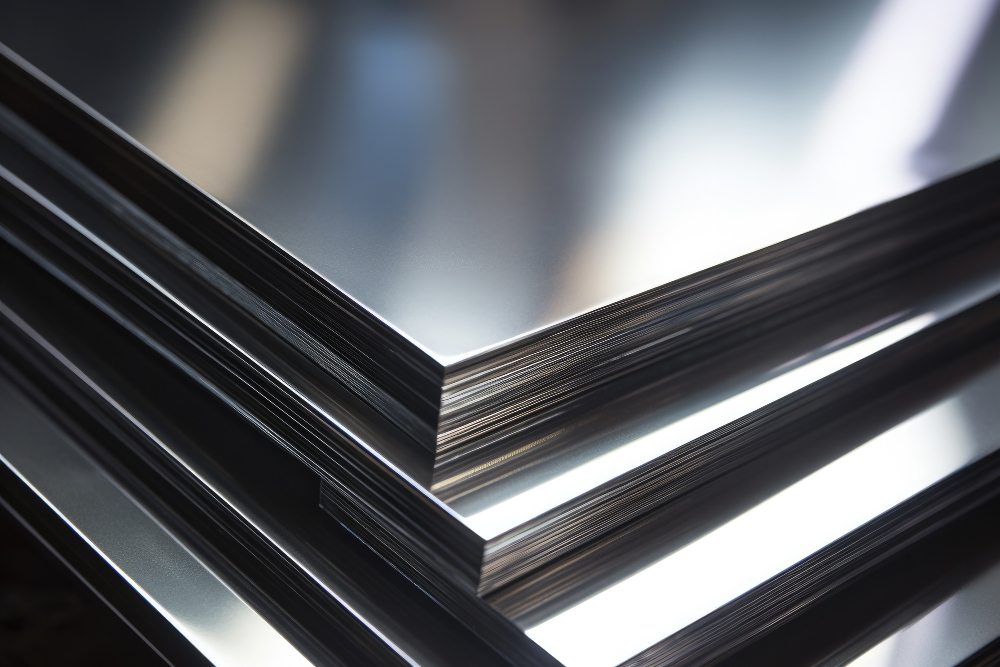

Sheet Metal: Properties, Types, and Applications

Sheet metal is one of the most widely used metal materials in the industrial, construction, and automotive sectors. Its durability, workability, and cost-effectiveness make it suitable for both industrial and decorative projects.

This guide will cover what sheet metal is, its properties, types, applications, and advantages in detail.

What is Sheet Metal?

Sheet metal is a material produced in thin metal sheets available in various thicknesses and dimensions. It is usually made of steel, stainless steel, or aluminum. Its high strength and workability make it suitable for a wide range of applications.

Properties of Sheet Metal

- Durability: Resistant to heavy loads and impacts.

- Flexibility: Suitable for cutting, bending, and shaping processes.

- Corrosion Resistance: Especially galvanized or stainless sheet metal is resistant to rust.

- Economical: Offers cost advantages due to long lifespan and high durability.

- Variety: Can be produced in different thicknesses, widths, and alloys.

Types of Sheet Metal

Sheet metals vary depending on the purpose and alloy type:

1. Carbon Sheet

- Low-cost and widely used.

- Durable but sensitive to corrosion.

2. Stainless Sheet

- Resistant to moisture and chemicals.

- Preferred in decorative applications due to its aesthetic appearance.

3. Aluminum Sheet

- Lightweight and corrosion-resistant.

- Widely used in construction and automotive sectors.

4. Galvanized Sheet

- Provides extra resistance to rust due to zinc coating.

- Commonly used in roofs, facades, and industrial applications.

Applications of Sheet Metal

Sheet metal is versatile and used in many industries:

1. Construction

- Roof coverings, facade panels, ceiling systems, and column structures provide durable solutions.

- Lightweight and easy to install, enabling fast applications.

2. Automotive and Transportation

- Used for vehicle bodies, chassis, and load-bearing parts.

- Durable structure ensures long-lasting and safe solutions.

3. Machinery and Industry

- Durable in machine frames, equipment, and piping systems.

- Workability makes it suitable for various industrial applications.

4. Food and Chemical Industry

- Hygienic and stainless sheets are used in food production facilities.

- Safely applied in chemical tanks and piping systems.

5. Decoration and Furniture

- Sheet metal panels are used for decorative panels and furniture in modern interior and exterior designs.

Advantages of Sheet Metal

- Durable and Long-Lasting: Resistant to heavy loads and impacts.

- Easy to Work With: Cutting, bending, and installation are simple.

- Versatile Applications: Suitable for construction, automotive, industrial, and decorative purposes.

- Corrosion Resistant: Especially galvanized and stainless sheets have long lifespans.

- Economical and Recyclable: Durable and environmentally friendly.

Sheet Metal Selection Criteria

- Material Type: Carbon, stainless, aluminum, or galvanized sheet should be chosen according to project requirements.

- Thickness and Size: Should be determined based on load and application area.

- Surface Type: Glossy, matte, or coated surfaces should match project needs.

- Workability: Choose sheet metal suitable for cutting, bending, and installation.

Sheet Metal Prices

- Carbon Sheet: Affordable and suitable for general purposes.

- Stainless Sheet: Higher price, durable, and corrosion-resistant.

- Aluminum Sheet: Lightweight, mid-range price.

- Galvanized Sheet: Mid-range price, extra corrosion resistance.

Other factors affecting price include delivery time, quantity, and surface treatment.

Maintenance and Storage

- Regular Cleaning: Wipe with a damp cloth.

- Protection from Chemicals: Keep away from corrosive substances.

- Storage: Store in a dry and ventilated environment.

Sheet metal is an important material in construction, automotive, industry, and decoration sectors due to its durability, workability, and cost-effectiveness. Choosing the right material type, thickness, and surface finish ensures long-lasting, reliable, and economical solutions for your projects.