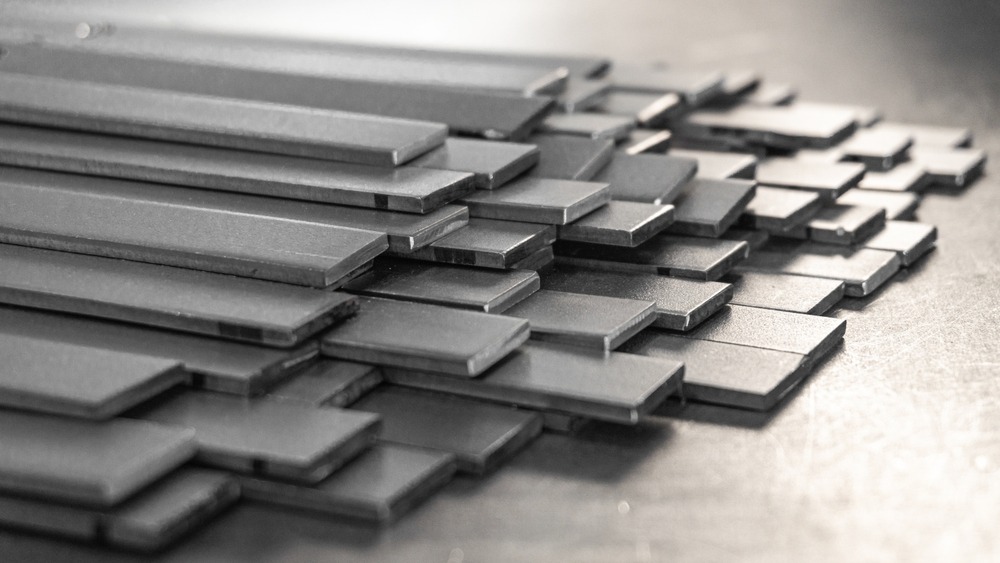

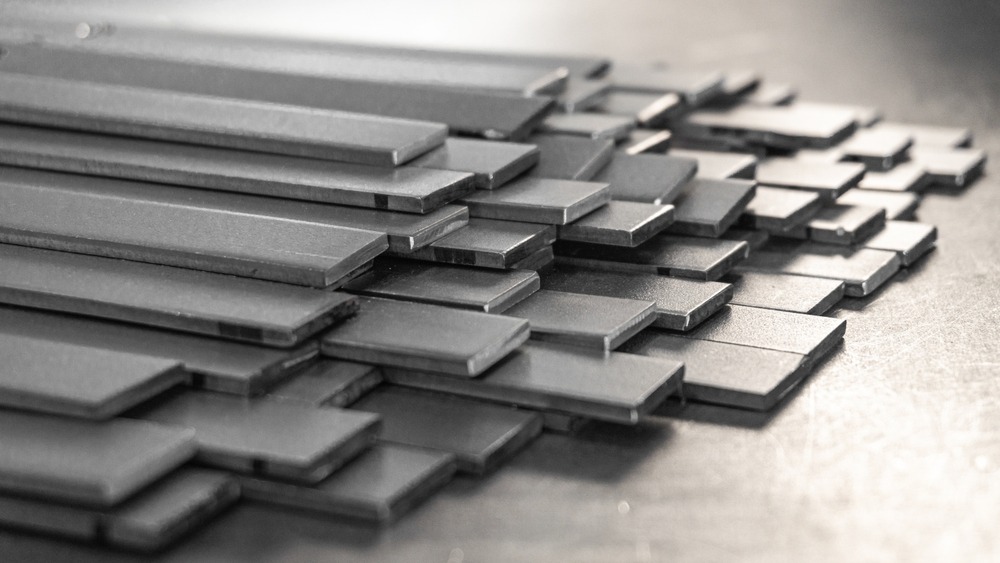

Stainless Steel Flat Bar Features, Applications, and Advantages

Stainless steel flat bar is widely preferred in construction and industrial sectors due to its durability, aesthetic appearance, and corrosion resistance. Its long-lasting and sturdy structure provides reliable solutions for various projects.

This guide covers what stainless steel flat bar is, its features, applications, advantages, and selection criteria in detail.

What is a Stainless Steel Flat Bar?

A stainless steel flat bar is a flat, long, and typically rectangular stainless steel profile. It is commonly used in staircases, railings, frames, and various mounting systems.

In terms of quality, 304, 316, and 430 stainless steel are commonly preferred:

- 304 grade: Suitable for general use, corrosion-resistant.

- 316 grade: Resistant to saltwater and chemical environments, ideal for marine and chemical industries.

- 430 grade: Magnetic and cost-effective option.

Production Process

The production of stainless steel flat bars involves the following steps:

- Raw Material Preparation: High-quality stainless steel sheets are selected.

- Cutting: Sheets are cut to the required length and width.

- Heat Treatment: Mechanical strength is enhanced.

- Surface Treatment: Options include polished (mirror) or matte (satin) finishes.

- Bending and Packaging: Shaped as required and prepared for shipment.

Stainless Steel Flat Bar Features

- Corrosion Resistance: Resistant to moisture and chemical environments.

- High Durability: Can support heavy loads.

- Easy Workability: Suitable for cutting, drilling, and welding.

- Aesthetic Appearance: Polished or matte finishes suitable for decorative applications.

- Heat and Chemical Resistance: Withstands high temperatures and chemical exposure.

Applications

Stainless steel flat bars are used in various sectors for multiple purposes:

1. Construction and Architecture

- Stair steps, railings, and frame systems for durability.

- Facade cladding for aesthetic appeal.

2. Machinery and Industry

- Suitable for machine frames and support elements.

- Reliable for heavy load-bearing structures.

3. Food and Chemical Industry

- Safe for use in hygienic production facilities.

- Corrosion-resistant in chemical tanks and piping systems.

4. Marine and Energy Sector

- Preferred in ship and yacht construction due to saltwater resistance.

- Used in energy projects for pipes and support systems.

Advantages of Stainless Steel Flat Bars

- Long-lasting and Durable: Corrosion-resistant and ensures long service life.

- Easy to Process: Suitable for cutting, bending, and assembly.

- Aesthetic Appearance: Compatible with modern designs through polished or matte surfaces.

- Cost-Effective: Durable structure provides long-term savings.

- Environmentally Friendly: 100% recyclable and eco-friendly.

Selection Criteria

When selecting a stainless steel flat bar, consider the following:

- Quality and Alloy: Choose 304, 316, or 430 stainless steel based on the project.

- Thickness and Width: Select dimensions appropriate for the intended use.

- Surface Type: Polished (mirror) or matte (satin) finishes according to application.

- Workability: Suitable for cutting, bending, and assembly.

Pricing

Prices of stainless steel flat bars vary depending on quality, thickness, width, and manufacturer:

- 304 grade: Mid-range price, suitable for general use.

- 316 grade: Higher price, suitable for marine and chemical environments.

- 430 grade: Economical, magnetic, and suitable for some chemical environments.

Other factors affecting price include delivery time, quantity, and surface treatment.

Maintenance and Storage

- Regular Cleaning: Wipe with a damp cloth.

- Protection from Chemicals: Keep away from corrosive substances.

- Storage: Store in a dry and ventilated area.

Stainless steel flat bars are important materials in construction, industry, food, and marine sectors due to their durability, aesthetic appearance, and long lifespan. With the right quality and size selection, you can achieve economical and reliable solutions in your projects.