One of the most important production technologies in the metalworking sector, laser cutting and bending offers high precision, fast production, and excellent surface quality. Today, construction, automotive, machinery, defense, architecture, and industrial design are among the many fields where metal laser cutting and bending processes play a crucial role.

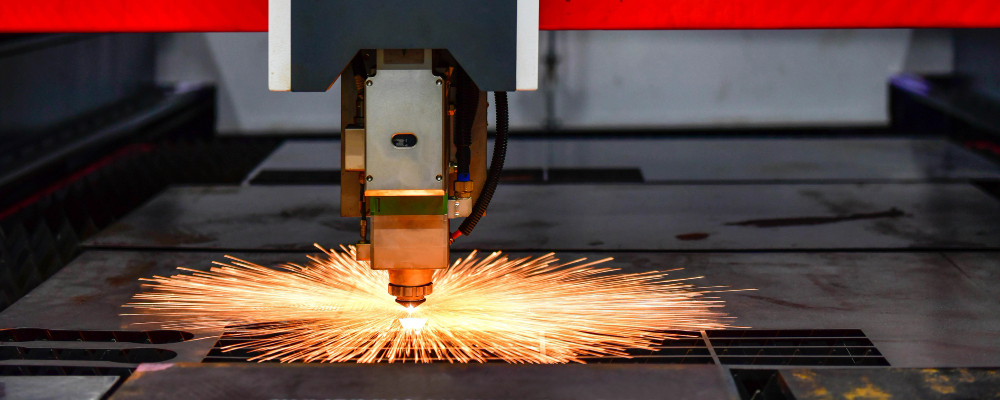

Metal laser cutting is a technology that uses a high-intensity laser beam to cut metal materials with precision. This method delivers excellent performance on a wide range of metals including stainless steel, aluminum, carbon steel, galvanized, copper, and brass.

Compared to traditional methods, laser cutting offers fewer errors, minimal burr formation, and allows even complex geometries to be cut perfectly. This ensures the highest quality standards for both mass production and custom project-based production.

High Cutting Precision: Provides clean cuts with ±0.1 mm tolerance.

Minimal Material Waste: Thin laser beam reduces scrap rates significantly.

Smooth Cutting Surface: Parts are ready for assembly without further processing.

Fast and Efficient Production: High-speed production with computer-aided (CNC) systems.

Design Flexibility: Desired shapes, patterns, or hole geometries can be easily processed.

Metal bending is a production stage that complements laser cutting. It shapes sheet or plate metals into the desired angles and forms. This process is performed using CNC press brake machines and ensures high repeatability.

Bending is ideal for industrial parts, machine enclosures, architectural elements, cabinet systems, and custom project designs.

Perfect Shaping: Parts are ready for assembly after cutting.

Repeatable Quality: CNC control maintains the same precision on every part.

Excellent Visual Results: Provides deformation-free, smooth, and aesthetic finishes.

Compatibility with Different Materials: Works with stainless steel, aluminum, carbon steel, and other metals.

Industrial Machine Parts

Architectural Facade Elements

Furniture and Decoration Products

Automotive Spare Parts

Advertising and Signage Systems

Construction Elements

Custom Prototype Production

Metal laser cutting and bending technologies have become indispensable in modern production for high precision, time efficiency, and aesthetic quality. This method allows companies to reduce production costs while increasing product quality.

When performed with professional equipment and an experienced team, laser cutting and bending processes elevate projects by saving both time and costs.